Well, I'm obviously not going to meet my deadline of June 1 for launch. Health and weather issues contributed to the delay, but we'll keep plodding along.

Well, I'm obviously not going to meet my deadline of June 1 for launch. Health and weather issues contributed to the delay, but we'll keep plodding along. In 2010, I developed a fuel flow problem in the boat. I found I wasn't getting fuel from the tank to the burner. I knew I had some kind of problem when I discovered that the day tank wasn't filling fast enough to compensate for the fuel used by the burner. That was confirmed on July 4, 2010 when we put the boat on the trailer and built a head of steam so that we could entertain spectators with the whistle during the annual Independence Day parade in Manzanita. I ran out of fuel and almost ran out of steam by the end of the parade. So, instead of launching in the river after the parade, the steamer went back in the boat barn and never did see water that year.

As described elsewhere on these pages, the fuel system is a fairly simple gravity-feed process - complicated by years of modifications. There are two tanks, one under the starboard seat forward, and the other the other nestled up under the deck in the bow. The starboard tank is at deck level and as such is about two feet lower than its companion. Fuel from the lower tank is pumped into the upper chamber by way of a chain-driven pump on the engine. The fuel is pumped to the upper tank where it is then gravity-fed to a day tank and from there to the burner. Pumping from the starboard to the bow tank serves to keep the upper tank full - facilitating the gravity feed. Excess fuel from the bow tank overflows back to the lower cell. The system also helps to keep the fuel moving. It's a good system and usually works well.

It bears mentioning here that I often mix the diesel with filtered crankcase oil. A 30% to 40% mix of oil doesn't create any negative issues nor does the mix appear to adversely affect the BTU rating of pure diesel. I did not empty the tanks and neglected to treat the fuel during the winter of 2009-10, and think that may be the problem. Untreated diesel can tend to gel, and if that is indeed what has happened, I may have two tanks of sludge.

So, that brings me to the project. The goal is to not only eliminate the fuel flow problem, but have the boat running and ready for launch by June 1.

May 1, 2011

I emptied the boat of everything that had been stored - tools, anchors, life jackets, wayward pieces of candy left over from last year's July 4th celebration. Seats and floorboards were dismantled to open access to the starboard tank. Next? Accessing the drain for that tank and attempting to empty it.

May 17, 2011

Instead of starting with the starboard tank, I decided to start at the other end of the system. I opened the line at the day tank and blew it out. No obstruction. It was clean. I then worked my way forward to the fuel filter, pulling it off the bulkhead and disassembling it. It was nearly as clean as the last time I had it out. No problem there either. I finally opened the final leg of the fuel line and after blowing it out - it was clean - I opened the valve from the bow tank. Lots of fuel there too! So - in sections - I have verified fuel flow all the way from the bow tank aft to the day tank. And yet I have been unable to get anything INTO the day tank!

I stopped there for the day, but a friend who was helping with this part of the troubleshooting sent me a list of suggestions later in the evening. All are worth taking a look at, so I'll use his email as a checklist and resume the investigation from there. There is one thing he mentioned that intrigues me...I had removed a line that had been used to pump fuel back into the day tank when it needed an additional shot of fuel. I hadn't used that pump and line in years, so I had partially disconnected it last year. In retrospect, that was about the time I developed the fuel flow problem. By eliminating the pump, but leaving the line place, "T-ed" into the main gravity feed line, have I essentially vented the system? Could that be the problem? Next - seal up the main line where it was penetrated by the auxiliary line and see if that solves the problem.

May 24, 2011

I started by completely removing the old auxiliary pump, the old fuel line and the "T" in the main fuel line. I also cleaned up the main line from the fuel filter to the day tank. We then we went back through the entire system, section by section. We made sure there was fuel flow all the way from the main tank to the day tank. There is now no problem with that fuel system. What was the problem in the first place? We really don't know. I suspect there were a number of small problems that added up to the big problem. All the lines have been cleaned - there could have been an obstruction that was cleared in that process and we just didn't find it. The auxiliary fuel pump, line and "T" have been removed and that line has been streamlined. That may not have been part of the problem, but it certainly didn't hurt to clean up that part of the system.

Now the dirty work begins. The bilge needs cleaning, the boiler may need cleaning and we just bought the paint for the interior of the hull. The bilge hasn't had a good cleaning since the hull was rebuilt after the accident - so it's overdue. The boiler really isn't going to be that bad, since we only fired it up once last season. We may try to eliminate that step at this time.

The rest of the deck plates have been pulled to allow for the bilge cleaning, and the seat bottoms and backs have been removed in preparation for painting. The plan is to paint the seats and the bulkhead - pretty much everything below the coaming that isn't a boiler or an engine.

June 1, 2011

Well, I'm obviously not going to meet my deadline of June 1 for launch. Health and weather issues contributed to the delay, but we'll keep plodding along.

Well, I'm obviously not going to meet my deadline of June 1 for launch. Health and weather issues contributed to the delay, but we'll keep plodding along.

Today was bilge-cleaning day. Not a fun day, but the forward and after sections are clean - only the sections athwart the boiler remain.

June 5, 2011

I began this page as a place to solve the mystery of the fuel that wouldn't flow. That problem (hopefully) solved, it has officially morphed into a report on the preparation for launch this season. Probably makes a better story anyway.

Bilge cleaning is complete - thanks to the First Mate. She finished the project while I was off doing reconnaissance of the site for the 2011 NWSS Steam Meet - Cathlamet, Washington. Meet organizer Norm Davis and I took advantage of a boat and a skipper who knows the area and spent a beautiful sunny day on the water. Again - thanks to the First Mate for finishing the job while I played!!!

As I said before, much of the wood from the seats, bulkheads and deck trim has been removed in preparation for painting. That process was delayed a couple of days by some bad wood filler. I found some old filler on the shelf - and by "old" I mean 20+ years - but rather than spending $5 to get some fresh material, I opted for the vintage stuff. Two days and a dozen gummed-up sanding disks later, I finally removed the last of the nasty stuff and I'm just about done with the sanding. I'm hoping the painting can begin tomorrow.

June 8, 2011

The best-laid plans and all that: Knowing that we were going to repaint the interior of the boat, I ordered another quart of the same make and color as the original. When our friend at the marina tried to match the number with the supplier, he was told that they no longer manufacture the paint with that number and that they could substitute the one that replaced it. Same brand (Bilgekote), same color (Gray), different number. We were assured that the color would match the old paint. A few days later, I got a panic call from the First Mate. She had begun to paint and told me that the colors didn't match. I said not to worry about it - the old stuff had been on there for years and was bound to have faded and weathered a bit. However, when I got home and checked it out myself, the phrase "didn't match" didn't even come close! The old paint could best be described as "powder gray". The new stuff is more like "charcoal gray". Other than the name "gray", they aren't even in the same spectrum! Now - that having been said - the new paint DOES LOOK pretty good, so we decided to go ahead and use it. The problem is that we didn't plan on painting everything in one outing. The rest will get painted after the season or maybe even next year. As a result, we now have a "patchwork" paint job - some powder, some charcoal - and it will stay that way through this steaming season. To make matters worse, we ran out of paint on the part of the project we do want to complete now. (Why is it that when the the instructions on the can say it will cover a certain square footage - you're sure to run out after only half that area has been covered?) I ordered more, but I'm only going to get it a quart at a time. $27.00 a quart - that's $108.00 a gallon. And we thought fuel was expensive!

The best-laid plans and all that: Knowing that we were going to repaint the interior of the boat, I ordered another quart of the same make and color as the original. When our friend at the marina tried to match the number with the supplier, he was told that they no longer manufacture the paint with that number and that they could substitute the one that replaced it. Same brand (Bilgekote), same color (Gray), different number. We were assured that the color would match the old paint. A few days later, I got a panic call from the First Mate. She had begun to paint and told me that the colors didn't match. I said not to worry about it - the old stuff had been on there for years and was bound to have faded and weathered a bit. However, when I got home and checked it out myself, the phrase "didn't match" didn't even come close! The old paint could best be described as "powder gray". The new stuff is more like "charcoal gray". Other than the name "gray", they aren't even in the same spectrum! Now - that having been said - the new paint DOES LOOK pretty good, so we decided to go ahead and use it. The problem is that we didn't plan on painting everything in one outing. The rest will get painted after the season or maybe even next year. As a result, we now have a "patchwork" paint job - some powder, some charcoal - and it will stay that way through this steaming season. To make matters worse, we ran out of paint on the part of the project we do want to complete now. (Why is it that when the the instructions on the can say it will cover a certain square footage - you're sure to run out after only half that area has been covered?) I ordered more, but I'm only going to get it a quart at a time. $27.00 a quart - that's $108.00 a gallon. And we thought fuel was expensive!

June 10, 2011

Things are progressing...just not very quickly. Paint takes a while to apply and even longer to dry, so the rest of the boat is sitting idle while waiting for that to happen. The First Mate thinks she has the last of the Charcoal Gray done, so now it's just a matter of waiting until it's dry enough to work around it.

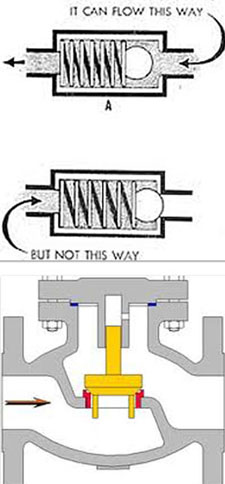

Meanwhile, I've tackled a couple of other issues. The hand feedwater pump is good for a lot of "one-arm" exercise, but not much else. It won't move water. It's a fairly new LeRoy Mietzner pump, so I'm pretty sure there is nothing wrong with the pump itself. It has check valves on both the inlet side and the outlet side to make sure the water goes in only one direction. Since they ARE check valves - a common source of waterflow problems - I started there. I took both valves off the pump and blew counterdirection through them. I could blow air through them the wrong way around, so I disassembled them at the workbench. As soon as I saw the innards, I was pretty sure I had nailed the problem. They are identical ball valves - probably not the best choice of check valve for that application. But the clincher was that the ball was made of plastic! Or nylon - something like that. When removed from the housing, the ball showed a definite erosion ring surrounding the point where it comes in contact with the valve seat. In the past, I have discussed check valves with Ron Fossum and I know he holds strong opinions on the subject, so I rang him up. The result of the conversation is that we have identified likely replacement candidates - lift valves (bottom) as opposed to ball valves (top). I'll be in Portland next week and will go by Paramount Supply and pick them up. That's one disadvantage of living at the coast...the good supply houses are a hundred miles away!

Meanwhile, I've tackled a couple of other issues. The hand feedwater pump is good for a lot of "one-arm" exercise, but not much else. It won't move water. It's a fairly new LeRoy Mietzner pump, so I'm pretty sure there is nothing wrong with the pump itself. It has check valves on both the inlet side and the outlet side to make sure the water goes in only one direction. Since they ARE check valves - a common source of waterflow problems - I started there. I took both valves off the pump and blew counterdirection through them. I could blow air through them the wrong way around, so I disassembled them at the workbench. As soon as I saw the innards, I was pretty sure I had nailed the problem. They are identical ball valves - probably not the best choice of check valve for that application. But the clincher was that the ball was made of plastic! Or nylon - something like that. When removed from the housing, the ball showed a definite erosion ring surrounding the point where it comes in contact with the valve seat. In the past, I have discussed check valves with Ron Fossum and I know he holds strong opinions on the subject, so I rang him up. The result of the conversation is that we have identified likely replacement candidates - lift valves (bottom) as opposed to ball valves (top). I'll be in Portland next week and will go by Paramount Supply and pick them up. That's one disadvantage of living at the coast...the good supply houses are a hundred miles away!

Back at the beginning of this marathon report, I discussed the fuel tanks. When I need to, I am able to check the fuel level in the bow tank by simply using a dip stick in the fill tube - it's a straight shot. But the starboard tank is a different matter. The fill tube is made up of a rather convoluted assortment of angles that resist any such measurement. There was once a plastic sight gauge attached to the tank, but it was in the tight space between the seat box and the fuel tank and was nearly impossible to see even before it clogged up. And it was absolutely no help when it came time to try to judge when to stop the fuel flow from the diesel pump to avoid a messy overflow. So I'm putting a new gravity gauge on the tank and then running the tube all the way over to the port side where I will be able to see it from both the filler spout as well as the helm. I'm just waiting for paint to dry to install it.

June 23, 2011

The fuel sight tube has been installed and the boat is ready for de-winterization. I'll haul it out of the barn, install the deck plates, wash it and re-connect all of the lines that were opened to prevent damage during the cold weather. The check valves were not in stock when I went to Portland, so I had to order them. They should be here within a week and installation of the feedwater pump shouldn't take too long after that. With a proper feedwater pump, I'll be able to run a hydro test and then I'll fuel up and fire up - probably by the first of next week.

July 3, 2011

Still no sign of the check valves. Paramount Supply told me they'd be in around the 28th of June, but they're not here yet. If they aren't in Tuesday's mail after the holiday, I'll have to do a search.

Here's an interesting follow-up to the fuel flow problem. After determining that there was no obstruction in the fuel line, I had been perplexed by the fact that I couldn't get anything to show in the sight glass for the day tank. Today, I filled the bow tank to the point where it's overflowing into the starboard tank - so I KNOW it's full. Still - there's only about 1/3 showing on the sight glass. I fired up the boiler and built up about 100 pounds of steam pressure - that takes about a half-hour on this boat. Now, running for a half-hour should have deleted an entire day tank full of fuel...but the sight glass only dropped about two inches in that time. So - I'm obviously getting fuel flow - (you mean I went through this entire process when there was no problem?) - but then why is the sight glass not reflecting the proper bow tank fuel level? The only thing I can think of is that the day tank is full, but for some reason the sight glass isn't showing that. Some kind of obstruction in the connections to the glass? For now, I'm going to put the problem on the back burner. We'll keep the boat on the trailer and haul it in the Independence Day parade tomorrow. If it works okay, we'll probably take it directly to the ramp and launch it in the afternoon. Any further work can be done at dockside.

July 19, 2011

I'm overdue for an update, so here's the latest:

We ran the boat in the parade. That ride is getting more popular each year. This time, we had 16 people on board! I fired the boiler and we blew the whistle all along the parade route. I usually have to re-fire another two or three times just to keep at least 100 pounds of steam for the whistle. We toot a lot, and the people along the parade route love it!

There was no sign of a fuel problem (the sight glass level at the day tank dropped a couple of inches and then stabilized) so, following the parade we went straight to the boat launch and put her in the water. The plan was to keep steam up and go out for a cruise after a barbecue, but as soon as I put her in the water, I noticed another problem! There was no pressure at the feedwater pump. None. So, I steamed her a mile over to the dock and parked her.

The weather turned bad after that (why is it raining so much in July?) so for the next couple of weeks there was no opportunity to do anything other than periodically bail rainwater out of the boat. There was a festival here in town this last weekend and the organizers had asked if I would give rides in the boat. I told them I was having problems but had persuaded a fellow steamer to join us. Al and Sue Dunlap brought CHENG TZE from Spokane, Washington to the mini-meet at Siltcoos Lake and were kind enough to stay an extra week on the Oregon coast and participate in our event. Since I knew his boat was running well, I fired mine up with the intention of just sitting at the dock and looking pretty at the festival. While Al was giving rides, I had the engine running at the dock. People were watching her turn over and were satisfied with my excuse for not giving rides when all of a sudden there was - what can best be described as a "gurgling" noise - and within five seconds, I had pressure at the feedwater pump! I wasted no time - grabbed the next people in line - and loaded them in for a ride. She ran great! Pump pressure two or three pounds over boiler pressure - boiler water level constant - hotwell no longer discharging condensate out the overflow - just like it's supposed to be! At the completion of that ride, I dropped that group at the dock and loaded a second party. Halfway through the second ride however, the feedwater pump pressure began to dramatically decline, so we quickly headed for home. I offloaded that group and once again let the engine run while tied to the dock. After about 15 minutes, another "gurgle" and instant feedwater pressure! Knowing I couldn't trust the situation to last, I offered no rides this time. Sure enough, after a few minutes, I lost pressure again.

So, what is it? Air lock of some kind? I'm not sure, but there really isn't much between the hotwell and the pump, so it shouldn't be terribly hard to diagnose. When it quits raining again (if it ever does), I'll dive into the bilge and tackle that problem.

Later on the 19th

It turned out to be halfway nice this afternoon, so I pulled the hose that connects the hotwell to the feedwater pump - it looks like new. No problem there. I'll check a couple of other connections before tearing into the pump itself.

July 31, 2011

I haven't been a total slacker over the past two weeks...I just haven't updated this report.

As I said, I pulled the line between the hotwell and the feedwater pump and it looked OK. I then went back to the hotwell itself - checking the tube between the tank and the hose. All clear there. In order to check the interior of the hotwell, I had to pull the float mechanism in the Al Giles system. While the float was removed, I checked to make sure the valve was working properly. No problem. Then I noticed that - in spite of it having been drained - there was still a couple of inches of water at the bottom of the tank. I ran a wire through the drain valve and immediately cleared an obstruction. Once the tank was drained - for real this time - I ran my hand over the tank bottom. It was covered with about a half-inch of - what can best be described as - goo. The pick-up for the feedwater line is about an inch above the goo, so it didn't take me long to figure that perhaps the filter on the pick-up is coated with the same stuff. I cleaned goop from the bottom of the hotwell and cleaned the filter as best I could with a brush and cleaner. That part of the line is soldered in place with no way to remove it other than with a torch or hacksaw. If my cleaning job doesn't work, I'll have to consider one of those alternatives. But I have high hopes that the cause of my intermittent feedwater problem is due to a clogged pick-up strainer at the hotwell. It will probably be a couple of days before I can steam up to check on the system. More then.

August 7, 2011

I steamed up with high hopes...and had them promptly dashed! When I had enough pressure, I fired the engine and the feedwater pressure came right up...and then - as always - slowly declined to nothing. Very, very frustrating! So I started from the beginning again - I opened the feedwater lines at every connection. The condensate runs from the hotwell to the pump and from the pump it runs through two pre-heaters that surround the condensate exhaust line. From there, it runs into the economizer. The economizer is simply a coil in the dome of the boiler. Water running through the economizer is heated by the fire to bring it up to boiler temperature. The heated water then passes through a check valve and into the boiler. I had water at every connection with the possible exception of the economizer exit where the flow was lower than I thought it should be. But blowing through the economizer showed no obstruction there, so I knew I was good all the way to the check valve. I removed that, took it apart and cleaned it - although it really wasn't fouled - and put everything back together again. So now, I KNOW I have no obstruction anywhere in the line from the hotwell to the boiler. I fired it up again and - nothing. No pressure on the gauge. By this time, I'm seriously considering a "For Sale" sign for the boat. My friend Ray - who has been helping me troubleshoot this problem - showed up about that time and instead of listing it for sale, we put our heads together and went through everything one more time. We knew everything was good from the hotwell to the feedwater pump and we knew we were good from the pump to the boiler. That means everything except.... Yeah, that light bulb came on for both of us at the same time too! THE PUMP! I had overlooked the pump - probably because everything else was easier to check. I pulled the pump, put it on the workbench and opened it up. The thing wasn't too bad, but it was definitely fouled. There was crud that was preventing the exhaust valve from properly seating. I cleaned it up, put it back together and re-installed it. I fired the boiler, ran the engine and - VOILA - feedwater pressure! I started it and stopped it three times and it behaved perfectly each time. It never ceases to amaze me how such a small amount of foreign matter can cause such a big problem! I'm headed out now for an evening steam. One more - hopefully positive - report after that!

Later on the 7th.

Had eight happy people out for a relaxing evening steam on the Nehalem River. Feedwater is working great! Need some packing for the high pressure piston, otherwise things are better than they've been in years!

August 16, 2011

We pulled the boat out of the water on the 8th. We needed to begin cleaning and polishing to get her ready for the annual NWSS meet at Cathlamet, Washington, but what should have been a one hour job ended up taking all day.

I was delayed a bit before we set out. I was late getting steamed up and then my friend Ray was delayed by a project he was working on, so we didn't get started until 10:30...after the tide had begun to ebb. We steamed up to the city dock with no problem, but when I tried to get the trailer ready for the retrieval, I found the cable in the winch drum had become hopelessly tangled. I vaguely remember that happening when we last used it two years ago. I disassembled the winch in the parking lot at the dock, but couldn't make make repairs myself, it was just too jammed up. I had to take it to a nearby repair shop where the cable had to be literally chiseled out of the drum. That took about three hours and all the while the tide was going out - way out - making boat retrieval more of a problem. I finally got the winch back on the trailer and got ready to haul the to the boat out of the water when I discovered ANOTHER problem - the switch on the electric winch didn't work. It was working before we started chiseling cable, but not now. By this time we were nearly at low tide and I had to drop the trailer wheels all the way to the bottom of the ramp. I had neither time nor patience for more repairs so I used the hand crank to winch the boat out of the water. That's a heavy boat and there's a reason we use a power winch! Still, we managed to get her settled on the trailer and moved to the driveway at home.

That was on Monday and we had until Thursday afternoon to get ready to go to Cathlamet. The first mate took over and spent hours cleaning and polishing her from stem to stern. Jan spent the better part of the next two days at the cleaning job until the boat just sparkled. I replaced the faulty winch with an old one I had on the shelf. We re-stowed all of the equipment on board, and by Thursday evening, we were ready to head north.

August 19, 2011

This is the third time I've attempted to finish this entry. The host for this website has been having problems and everything I wrote just disappeared when I tried to post it. Although that was frustrating, at least I should know what I want to write by this time!

We left Wheeler at about 9:30 Friday morning and took the Astoria bridge across the Columbia River. Once we crossed, it only took another 45 minutes to get to Cathlamet and we were at Elochoman Marina by 11:30. I wanted to get an early start so we could get the inspection out of the way.

We are fortunate here in the northwest that we are not subject to government inspection of our pressure vessels. The agencies involved have elected to not subject us to regulation as long as we police ourselves. To that end, the Northwest Steam Society has set up a program that requires pressure vessels to successfully complete an inspection prior to participation in any sanctioned event. Most of our members live closer to a convenient inspection point than I do and were able to complete this requirement prior to this event. Those who have been following this log know that we have had problems getting the boat ready for this season, and so this was really the first opportunity to get the inspection. I did my own hydro test earlier and passed with no problems, so I was ready when we got to Cathlamet. The inspection process is fairly straightforward: The boiler is filled to the top with water and then pressurized to 1 1/2 times the safety valve release pressure...in my case, 210 pounds. Pressure is monitored for 10 minutes to assure that there is no drastic drop. The bottom of the boiler is visually inspected for any possible leakage. The pipes and fittings are checked to assure that they are capable of withstanding boiler pressure. Finally, the boiler is steamed up until the safety valve pops...just to make sure it works. Inspection complete, we headed for the launch ramp, grabbed a spot at the dock and then spent the rest of the day and evening doing what we do best at steam meets - talking with other steamers.

Saturday we steamed up, loaded the boat with eight other people and headed out for a cruise. The first thing we did - or tried to do - was to pose for a group photo. Trying to get 14 steamboats in a tightly-spaced group for a photo with the current moving them around can best be described as "herding cats". We spent nearly an hour trying to get the boats in position for the photo and when we got it, the current had nearly taken us into the rocks at the entrance to the marina. Then - photo taken - we had to extricate ourselves from the group. Somehow - no one is sure just how - we managed to untangle the formation and head out into the Columbia River with no major casualties. (Photo by Gerald McClellen)

The reason for the trip out into the Columbia was to visit Puget Island and attempt to cruise through Birnie Slough. Both ends of the slough are difficult to negotiate with a lot more shallow water than channel. Although we were given charts of the area, finding the narrow entrance to the slough proved difficult. I actually ran aground at one point and had to back out before we became mired in the sand. A helpful bystander finally saw our plight and piloted our fleet into the slough and we were on our way. Birnie Slough is about four miles long and is not very wide. Docks and houseboats on both sides make the way even narrower. The word had gotten out that we were going to be cruising the area and we had a lot of spectators in the homes and on the shore. I'm sure we were quite a sight for the locals - a fleet of steamers not being what they were used to seeing along the waterway. Of course, we felt obligated to respond with a whole lot of whistle tooting!

One side note about the whistle tooting: I was having some feedwater issues as we crossed over to Puget Island and so was using the injector to make up water in the boiler when we went aground. In the excitement over trying to extricate ourselves, the boiler continued to fill. When I discovered what was happening, I had way too much water in the boiler. I dropped the water level a bit, but since I had been having problems getting water INTO the boiler, I was reluctant to take too much OUT of it. The whistle uses the steam at the top of the boiler and as a result of the overflowing, simply "gurgled" when we tried to blow it. Embarrassing, but it kept us going. As fate would have it, about that time the feedwater system began to function properly and we continued the voyage with a lot more water in the boiler than needed. As described earlier, when working properly the boiler level will maintain itself and so we continued the trip with an overfull boiler and a slightly "gurgly" whistle.

We finished the trip through Birnie Slough in about an hour, negotiated our way through some tricky water at the exit and re-entered the Columbia about five miles above Cathlamet. Although we had the current with us on the return trip, the tide and the wind were against us and so it took another hour to finish the excursion. Since the First Mate had packed the boat with wine, cheese, beer and crackers, we didn't go hungry - or thirsty - but a lot of the passengers were mighty glad to see the bathroom when we docked!

I was very pleased with the performance of the boat on that cruise. With the exception of that one time at the beginning of the trip, the feedwater system performed perfectly. With the photo stop, the trip across to the island and finding our way, the cruise through Birnie Slough and the return trip, we traveled about 12 miles. That may well be more than the total for the past 10 years! It's certainly the longest trip we've made in that time. It's obvious that the crud in the feedwater pump was the source of my problems and I'm very pleased that we are going to be able to cruise problem-free as long as the pump is clean. Somewhere in a box of parts, I have a filter that I'll attempt to install in that line. Then the filter - which can be easily cleaned - can collect the crud instead of the pump. Oh, and the fuel level on the trip was no problem at all, so the issue at the beginning of this report is official now a "non-issue".

After our big day on Saturday, Sunday was more relaxed. By mid afternoon, several of the boats were ready to come out of the water, so I donned my chest waders and worked as the "in-water" retrieval guy. That took most of the afternoon - right up to the point where those of us still in town headed up the street for pizza.

Monday, we all left town and headed our separate ways. Five of us elected to head west to Astoria, Oregon to the John Day River for a short cruise. The ferry across the Columbia normally holds nine cars. We had two cars and a motorhome - all towing boats. They were a little dismayed to see us in line! They managed to squeeze us in with room for two extra cars, so only one truck at the end of the ferry line got left behind. Within an hour, we were at the boat ramp at the John Day.

It was another beautiful, sunny day and we steamed up and launched in record time - anxious to explore the short but beautiful river. As I headed out, I could tell immediately that my euphoria of the weekend was going to be short-lived. I had no feedwater pressure. Again. This time however, I really didn't worry about it too much...I knew that the pump was probably fouled again, so we just stopped to top off the water tanks whenever possible on the eight mile trip and used the injector to keep the boiler full. At one point on the trip, my water tanks went dry and I had to beg a tow from another steamer. Toward the end of the trip, we stopped for a spaghetti feed at the home of one of our members, then came back to the ramp and pulled out. We are located a little over an hour from Astoria, and we were home by 6:00. All in all, a wonderfully satisfying trip!

So today, the boat is still on trailer in the driveway - waiting for me to pull the pump and clean it again. I've procrastinated a bit because I'm still looking for that filter. I figure I may as well install it while I have the pump on the bench.

(to be continued)