Olympia, Wash.

Dear Editor:

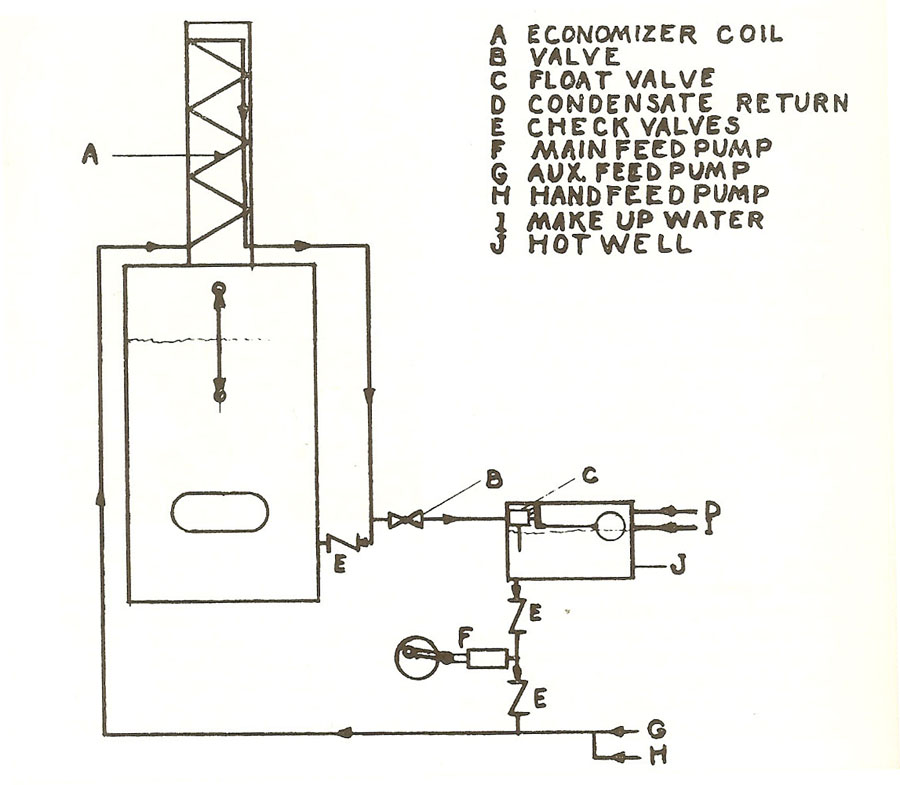

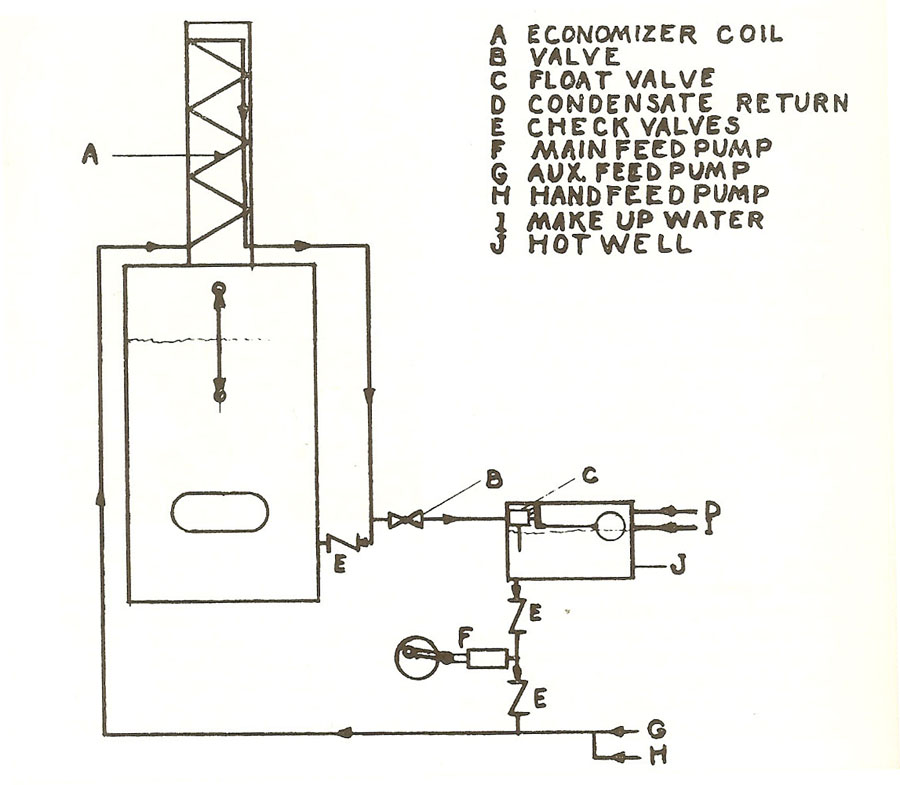

I have received a number of letters asking me about my automatic feed water regulating system. If you should see fit to print the enclosed schematic sketch, it might give some of the "boys" an idea of how it works. Basically it is very simple and has proven trouble free.

To start with, one must fill the boiler to its working level and also fill the hotwell to its desired height and adjust the float arm so that float valve C is closed. (This valve closes as the float ball rises and opens as it falls.) Now as the engine takes steam, the water level in the boiler will tend to drop, but the condensate being returned from the condenser is raising the level in the hotwell. Now as the level raises in the hotwell, it closes the float valve C, which allows the water from the feed pump to all go into the boiler. The feed pump must be capable of pumping more than the boiler can possibly require. (My pump has a capacity of 40 per cent over requirements.)

The tendency now is to pump the water out of the hotwell faster than it comes in, so the level drops and the float valve C opens slightly and allows some of the feed water to by-pass back to the hotwell. Thus the float valve C is maintaining the level in the hotwell and in doing so is also maintaining the water level in the boiler. Now, if we had a 100 per cent tight system, this condition would continue indefinitely, but as there is always some slight loss, due to leakage around the piston and valve rods and valve glands, and from blowing the whistle, or popping the safety valve, a little additional makeup water is required from time to time. Over a period of time the level will drop very slowly in the boiler, so to bring it back, all that is necessary is to add a little water to the hotwell.

Suppose we add, say one gallon, the float valve will then rise and close valve C and will allow all of the water being pumped by the feed pump to go into the boiler, thereby bringing the water level up in the boiler. So in a short while the gallon we added to the hotwell is now in the boiler, where we wanted it. Another very desirable feature of this set up is that the full output of the feed pump is going through the economizer coil, in the stack (A) and about 40 per cent of it is being continuously by-passed back to the hotwell, where the heated water builds up the temperature in the hotwell to about 160 degrees where it levels off. If, for some reason, float valve C should not hold, all one need do is to control this by-pass water manually by valve B. With the amount of economizer coil I have, I am putting feed water into my boiler at around 290 degrees and maintain about 160 degrees in the hotwell. I can add makeup water to my hotwell by an independent steam pump or can add it directly to the boiler. I also have a hand pump for the same purpose.

This system has now operated 200 hours and has had nothing done to it since the initial adjustment. The only thing that can happen is for the float valve C to start to leak from wear and this is easily repairable. If this should become apparent while operating, one only need to operate valve B by hand until the valve C is repaired.

I think you will find the sketch pretty much self-explanatory and I'm sure anyone using a similar system will find it absolutely satisfactory. In actual practice the float should be mounted fore and aft, so that rolling of the boat in a seaway will not cause it to work erratically. In a fore and aft position, the pitching of the boat is not fast enough or severe enough to make any difference.

Al Giles